Services

Modularization

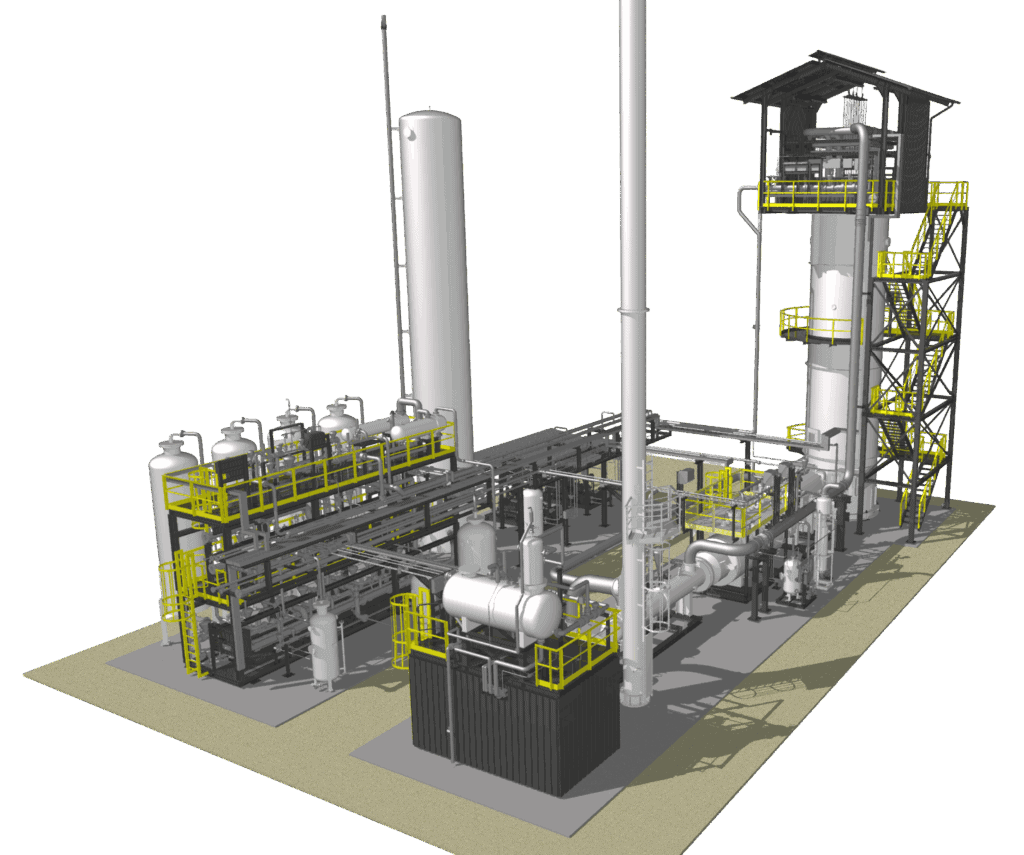

Modularization enables faster, safer, and higher-quality plant construction through offsite prefabrication of flexible, ready-to-install units.

Services

Modularization

Modularization involves manufacturing large parts of a plant off-site in a workshop and then transferring them to the construction site for assembly.

Modularization breaks down the plant into standardized, pre-designed units that can be prefabricated in a controlled workshop environment, ensuring high quality and reducing onsite construction time. Prefabricating modules offsite also reduces exposure to environmental variables like weather, leading to more consistent production and fewer delays. This approach significantly shortens construction timelines, as modules can be assembled offsite while site preparation continues simultaneously. It also enhances safety, as prefabrication minimizes the need for complex, hazardous work at the plant site, reducing the risk of accidents. Furthermore, modularization offers flexibility and scalability, enabling easy plant expansions or upgrades by simply adding or modifying pre-constructed modules.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAdvantages:

- Workshop fabrication allows for better quality control in a controlled environment, ensuring higher precision and consistency.

- Prefabrication reduces on-site construction activities, lowering exposure to hazards and improving overall worker safety.

- Modules can be built in parallel with site preparation, significantly reducing the total project timeline.

- Reduced labor hours on-site and minimized delays lead to lower overall project costs.

- A modular system with a high degree of prefabrication offers strong potential for standardization and cost reduction.

- Modules can be pre-tested in the workshop before delivery, ensuring functionality and reducing commissioning time on-site.

- Delivering preassembled modules minimizes the number of workers and equipment required on-site, improving logistics and workflow.

Safety

Controlled work environment during pre-fabrication and subsequently reduced work on site.

Quality

Quality assurance systems are easier to implement due to a stable working environment at fabrication site.

Planning

Planning efforts are initially higher but ensure smoother execution on-site where external factors abound.

Costs

Potential increase in CapEx due to engineering and shipment of modules is compensated by decreased OpEx.

Innovation

Requirement to think outside the box to tackle new challenges such as design and engineering of more compact and lightweight modules.

Services

Containerization

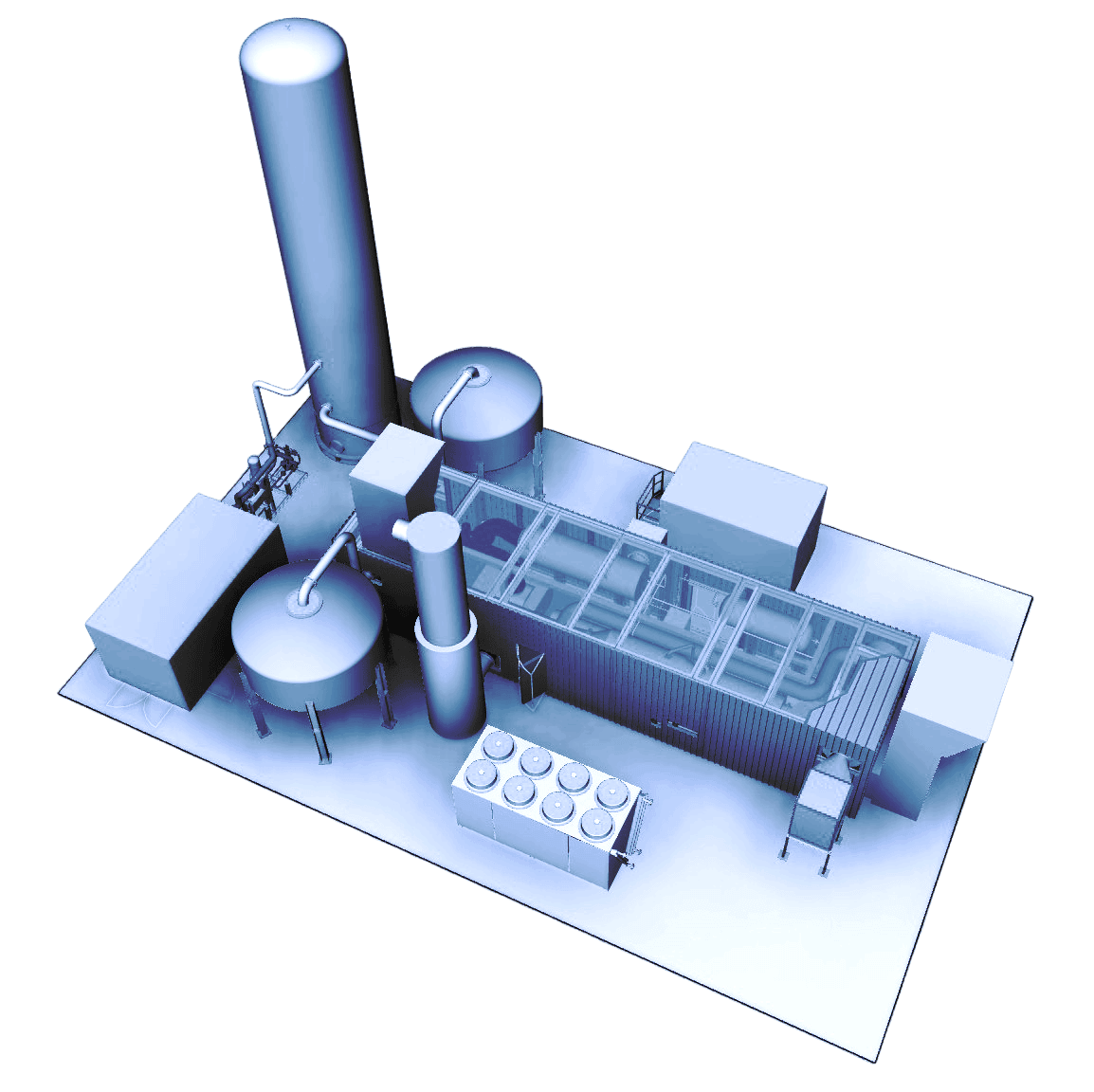

Containerized process plants are modular, pre-assembled systems housed in shipping containers, offering mobile and scalable solutions

Containerized plants provide a standardized, transportable solution by housing process units in prefabricated modules. They simplify logistics, reduce onsite installation time and costs, and arrive pre-installed, tested, and ready for commissioning. The compact, self-contained design improves safety and quality through controlled workshop fabrication and allows optimized pipe routing. Containerized units are scalable, flexible, and easily replicable, relocatable, or expandable, with a minimal footprint suitable for space-limited sites. This approach also enables rapid deployment, ideal for remote or temporary operations.

Prefabricated modules to the highest possible level

Small Layout

Minimized erection effort and time

Improvement of pipe routing acc. to process aspects

Obsolete building by the client

Possibility to relocate the complete plant is simplified

1 Lorem ipsum dolor

2 Lorem ipsum dolor

3 Lorem ipsum dolor

4 Lorem ipsum dolor

5 Lorem ipsum dolor

6 Lorem ipsum dolor

7 Lorem ipsum dolor

8 Lorem ipsum dolor

Contact

Optimize your business with advanced gas purification

Our experts are available to provide you with personalized advice. Contact us to find the best solution for your system!