Plants

High-efficient Nitrogen PSA

Plants / Generators

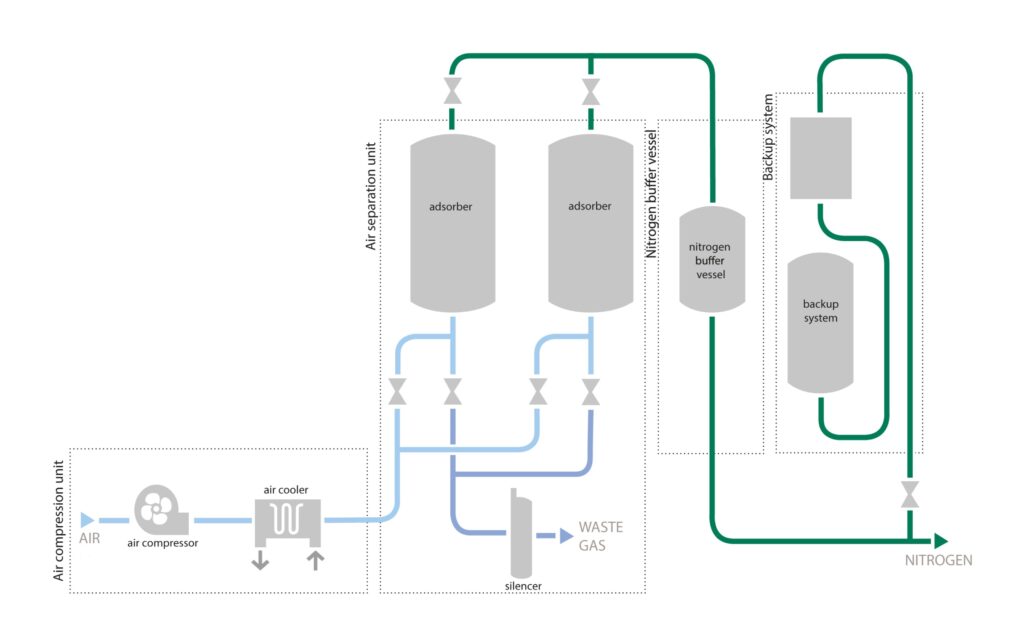

NITROSWING PSA plants generate nitrogen on-site directly from ambient air. The pressure swing adsorption (PSA) process uses carbon molecular sieve (CMS) to separate oxygen from the air at ambient temperature, leaving a nitrogen-rich gas stream.

HOW MAHLER NITROGEN PSA PLANTS WORK

PSA Technology for Efficient Nitrogen Generation

In the pressure swing adsorption process, ambient air flows over CMS adsorbers. The CMS preferentially adsorbs oxygen, allowing nitrogen to pass through as the product gas. By cyclically switching between adsorption and desorption phases, a continuous nitrogen stream is produced – fully automatic, with short start-up time and no operator required.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPlant data:

| Feedstock: | ambient air |

| Nitrogen capacity: | 200 to 4.000 Nm³/h |

| Purity (N2 + Ar): | up to 99,99 vol.-% |

| Pressure*: | about 6 – 9 bar(abs) |

* at exit nitrogen PSA unit; higher pressures on demand.

Benefits

Why Nitroswing?

Design for a long lifetime

High availability and reliability

Fast start-up , fully automatic and unattended operation

Completely pre-manufactured skids

Independent and low-cost on-site production

Product flexibility regarding flow and purity

Frequently asked questions

Questions about our nitrogen plants

What nitrogen purity can be achieved with NITROSWING plants?

With N2-PSA systems a purity up to 99,99 % (nitrogen + argon) can be reached, which corresponds to a remaining oxygen concentration of 100 vppm. An additional oxygen removal unit (DEOXO) can be supplied to achieve oxygen contents below 3 vppm.

What are the advantages of NITROSWING compared to liquid nitrogen supply?

Using the NITROSWING for on-site nitrogen generation reduces logistics costs, ensures a continuous supply, and allows the production of nitrogen directly tailored to process demands.

How do NITROSWING plants ensure a continuous and reliable supply of nitrogen?

The PSA cycle alternates between two adsorption vessels, which are supported by a buffer vessel and flow control. This ensures stable product flow, pressure, and quality.

Can custom configurations be provided?

Yes. Mahler AGS offers tailored solutions that account for site-specific conditions, such as building layout and noise limits.

Applications for our nitrogen Plants

Typical applications for our nitrogen plants

Petrochemical and refining industry

Metallurgical and steel industry

Glass and enamel industry

Chemical and pharmaceutical industry

Food industry

Electronics industry

Technical gases

Plan Your Nitrogen Plant with MAHLER

Get expert support for selecting and configuring your on-site nitrogen solution.

Information brochure

Our Process

End-to-end expertise for your gas system

With MAHLER, you don’t just get a gas plant – you get a full-service partnership. Our end-to-end approach includes professional project management, tailored engineering, high-quality in-house manufacturing, and long-term support. Each project follows a structured process – designed to deliver maximum reliability, efficiency, and value.

01

Planning & Engineering

We analyze your requirements and design the ideal system – tailored, efficient, and ready to scale.

02

Technology & Plants

We develop and produce your plant using advanced MAHLER gas technologies and in-house manufacturing expertise.

03

Delivery & Commissioning

From procurement to on-site installation – everything is coordinated and delivered from a single source.

04

Service & Optimization

We support you with maintenance, spare parts, and continuous optimization to keep your process efficient long-term.

Contact

Optimize your business with advanced gas purification

Our experts are available to provide you with personalized advice. Contact us to find the best solution for your system!