Plants

Efficient and Reliable

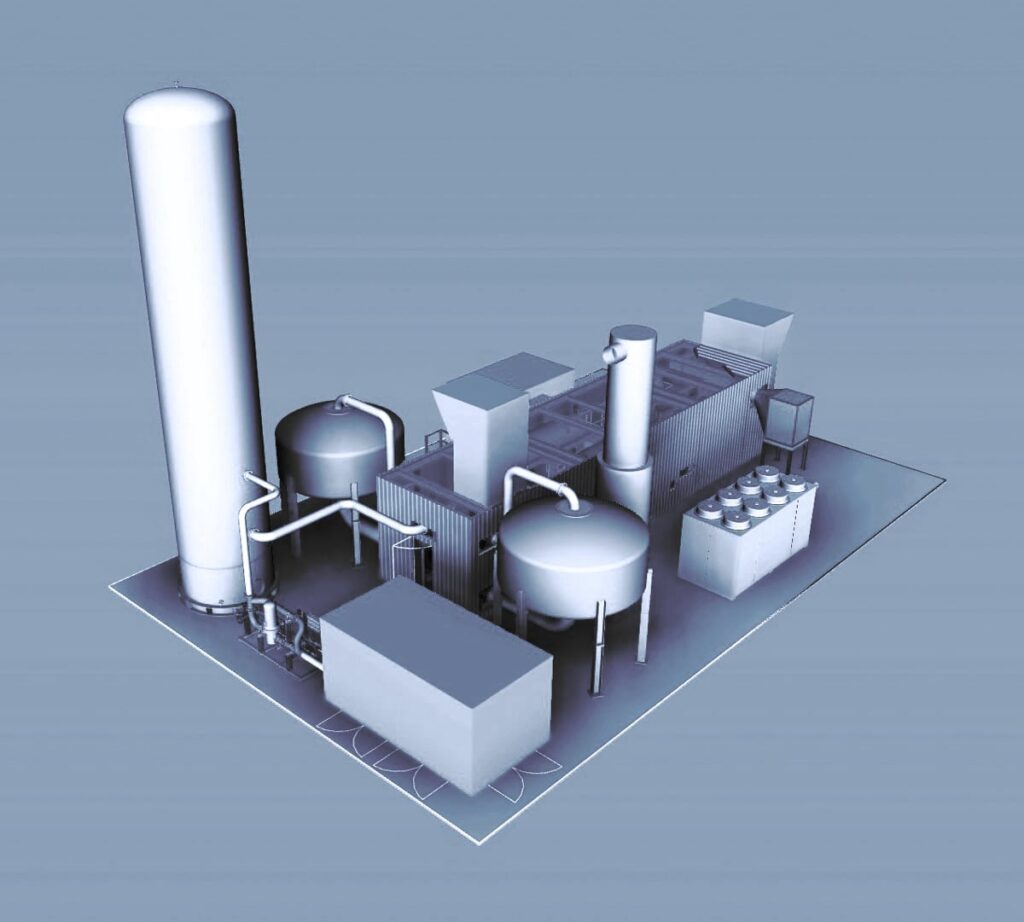

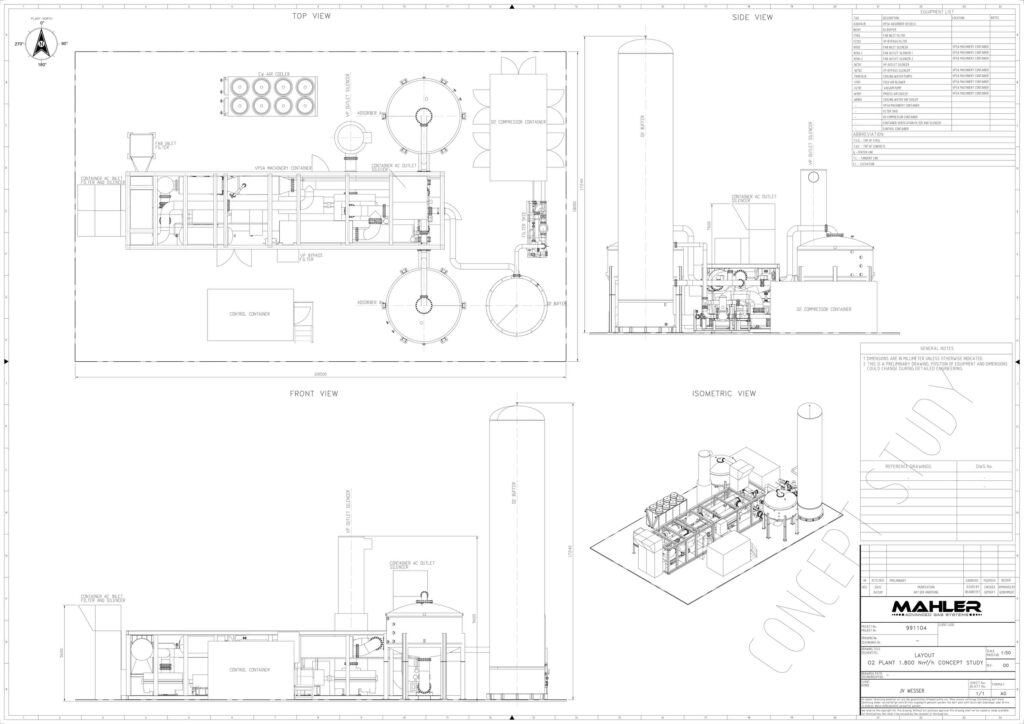

Oxygen Plants by MAHLER

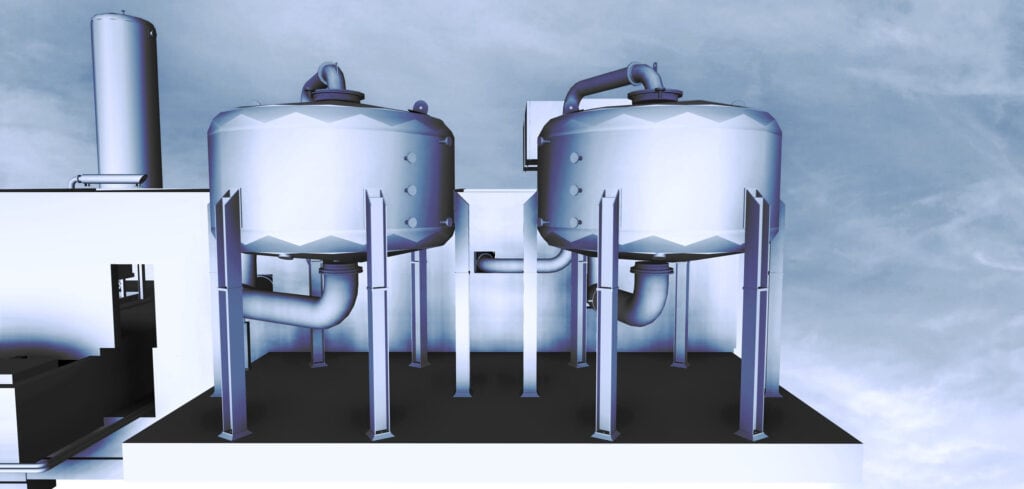

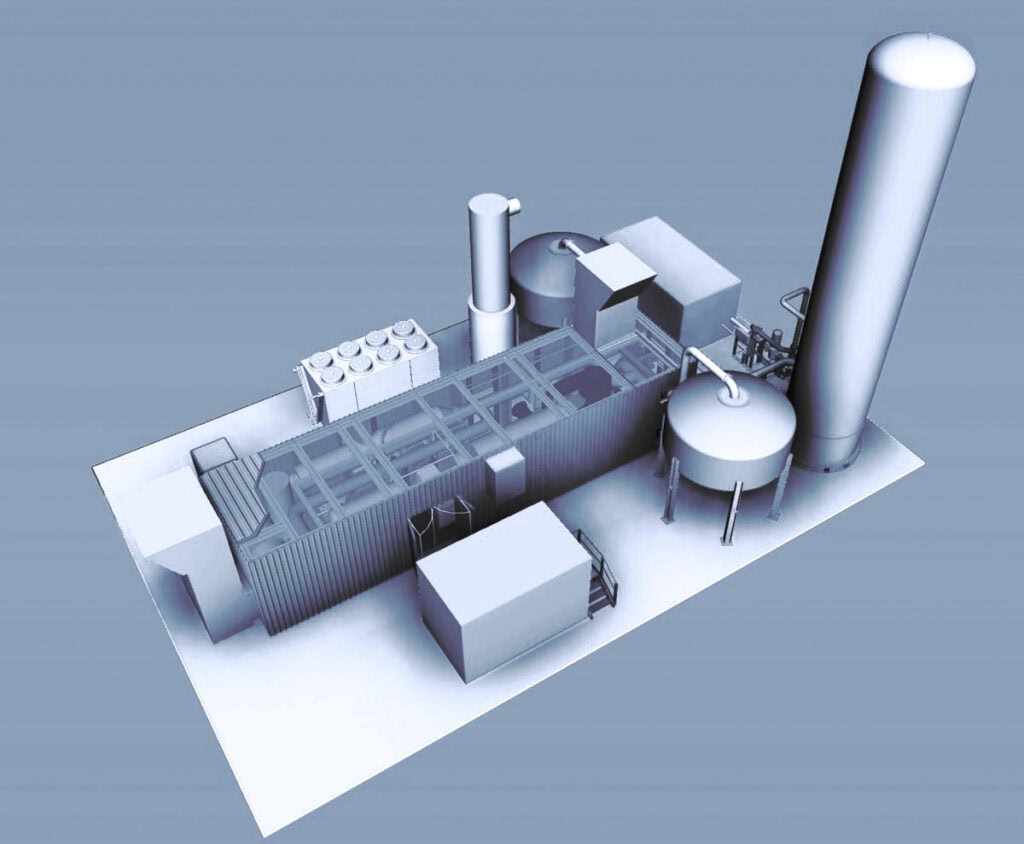

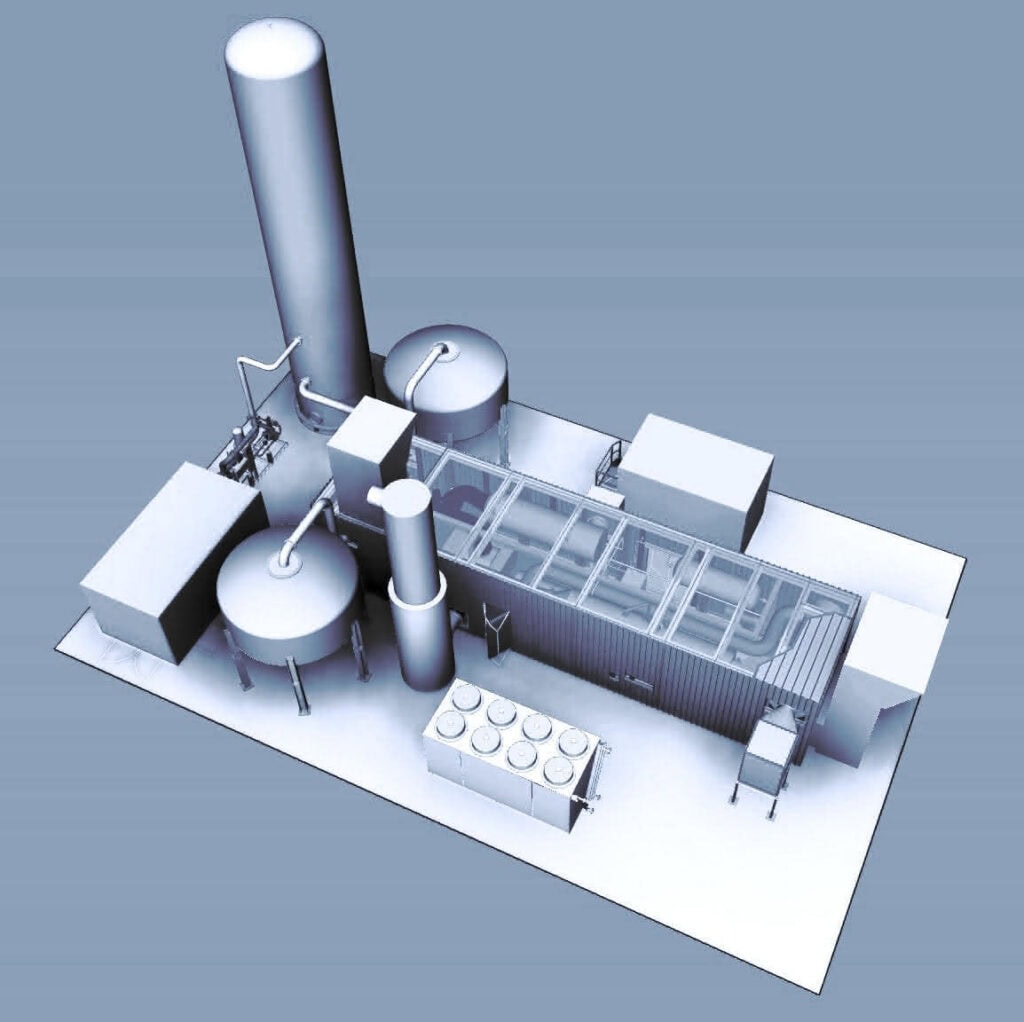

MAHLER designs and delivers high-performance oxygen generation systems based on VPSA technology - tailored to industrial requirements, scalable, energy-efficient, and built for continuous operation.

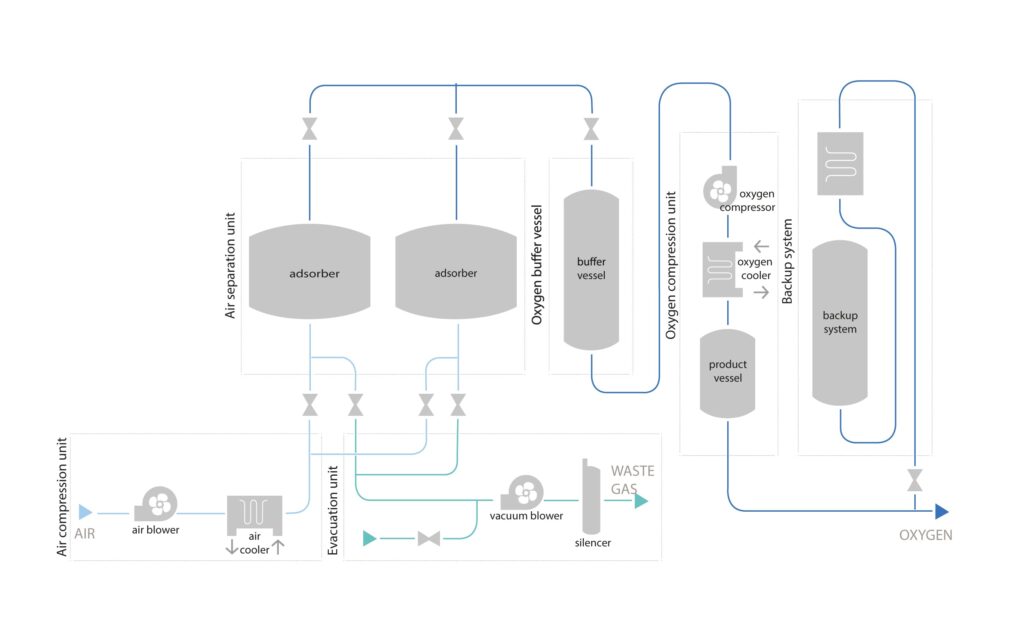

How MAHLER VPSA Oxygen plants work

Advanced VPSA Technology for Maximum Oxygen Efficiency

Using vacuum pressure swing adsorption (VPSA) with high-performance zeolites, MAHLER plants separate ambient air into a rich oxygen stream with purities up to 94 vol.-%. Our flexible designs allow investment- or energy-optimized configurations, adapted to your local requirements and production processes.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPlant data:

| Feedstock: | ambient air |

| Product gas capacity: | about 300 to 5.000 Nm³/h |

| Purity: | up to 94 vol.-% |

| Pressure*: | about 1,2 bar(abs) |

* at exit oxygen VPSA unit; higher pressures on demand.

Benefits

Why Oxygen VPSA?

Low-cost, on-site oxygen production

Fully automatic operation – no operating personnel required

Flexible product flow and purity levels

Fast start-up and automatic part-load adjustment

Remote monitoring and support

Compact, skid-mounted units for quick installation

High system availability and long service life

Frequently asked questions

Questions about our oxygen plants

Which oxygen purity levels can VPSA technology provide?

Due to the physical properties of the molecular sieve used, the maximum achievable oxygen purity is below 95 vol.% O₂. Typical product specifications range from 90 to 94 vol.% O₂. Mahler AGS also offers plants for purities below 90 vol.% O₂

Why is the maximum oxygen purity of a VPSA system limited to around 95%?

In addition to nitrogen and oxygen, ambient air contains approximately 1 vol.% argon. Due to the similar adsorption properties of argon and oxygen, argon is not effectively separated and remains in the product gas. This limits the maximum achievable oxygen purity to about 95%.

How energy-efficient is the VPSA process from Mahler AGS?

Compared to liquid oxygen from cryogenic processes, the VPSA process is significantly more energy-efficient and consequently more cost-effective. Specific energy consumption depends not only on the required product specifications but also on the climatic and geographical conditions at the plant site. We are happy to provide tailored advice for the optimal design of your oxygen plant.

What are the advantages of the VPSA process compared to cryogenic oxygen production?

Cryogenic air separation plants generate high purity oxygen (>99.5%) by cooling air to –183 °C. While highly effective for large-scale production, these systems are complex, energy-intensive, and generally only economically viable for very high capacities (> 10,000 Nm³/h).

Why are VPSA plants more energy-efficient for oxygen production than PSA plants?

Since oxygen makes up only ~21 vol.% of air, compressing the entire feed stream in a PSA system is energy-intensive - most of the energy is used to compress nitrogen, which is then emitted. VPSA systems avoid this by operating at low pressure and using vacuum for regeneration. Thus making it significantly more energy-efficient for oxygen production, even if the final oxygen product is later compressed.

How stable are the product conditions delivered by the VPSA system?

Due to the cyclic nature of the VPSA process, product pressure, temperature, flow, and purity may show slight fluctuations. However, with a suitable control and regulation system provided by Mahler AGS, these variations are minimized to such an extent that they do not cause any issues for downstream processes.

Can a Mahler AGS VPSA plant be integrated into existing processes?

Yes. Mahler AGS VPSA systems feature a modular design that allows flexible adaptation to site-specific requirements. This ensures seamless integration into existing production processes. Mahler AGS provides comprehensive engineering and integration support – from concept planning and interface definition to commissioning – ensuring smooth integration into your operations.

Is oxygen production based on VPSA technology carbon-neutral?

The plant is fully electrified. When operated with electricity from renewable energy sources, no direct greenhouse gas emissions are generated.

What service and maintenance services does Mahler AGS offer for VPSA systems?

Mahler AGS offers a comprehensive service portfolio covering the entire plant lifecycle. This includes commissioning and start-up support, preventive maintenance, spare parts supply, inspections, and remote assistance. Mahler AGS also provides additional services such as operator training, plant optimization, modernization and relocation, ensuring the long-term availability and efficiency of your VPSA system.

Applications for our VPSA Oxygen Plants

Typical applications for our oxygen plants

Petrochemical and refining industry

Metallurgical and steel industry

Glass and enamel industry

Chemical and pharmaceutical industry

Food industry

Electronics industry

Technical gases

Plan Your Oxygen Plant with MAHLER

Get expert support for selecting and configuring your ideal on-site oxygen solution.

Information brochure

Our Process

End-to-end expertise for your gas system

With MAHLER, you don’t just get a gas plant – you get a full-service partnership. Our end-to-end approach includes professional project management, tailored engineering, high-quality in-house manufacturing, and long-term support. Each project follows a structured process – designed to deliver maximum reliability, efficiency, and value.

01

Planning & Engineering

We analyze your requirements and design the ideal system – tailored, efficient, and ready to scale.

02

Technology & Plants

We develop and produce your plant using advanced MAHLER gas technologies and in-house manufacturing expertise.

03

Delivery & Commissioning

From procurement to on-site installation – everything is coordinated and delivered from a single source.

04

Service & Optimization

We support you with maintenance, spare parts, and continuous optimization to keep your process efficient long-term.

Contact

Optimize your business with advanced gas purification

Our experts are available to provide you with personalized advice. Contact us to find the best solution for your system!