Plants

Process Gas Membrane

Systems

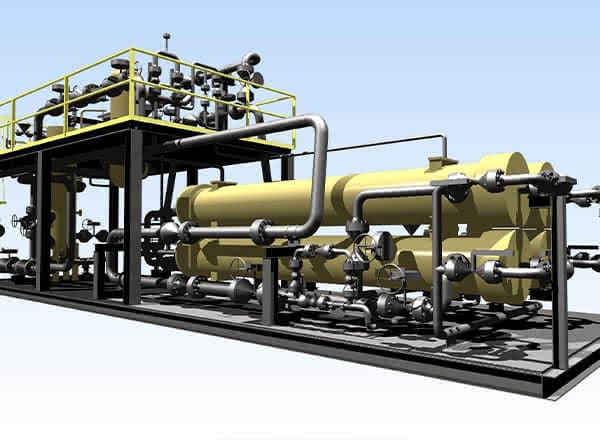

Completely packaged membrane units for purification and separation of process gases—tailored to your requirements, delivered as prefabricated skids, with high recovery and up to 99 vol-% product purity.

TAILORED GAS PURIFICATION SOLUTIONS

Compact membrane separation—customized for your process

Mahler AGS process gas membrane systems separate and recover valuable components from crude feed or off-gas streams (often used as HRUs). Beyond hydrogen recovery, the units can adjust syngas ratios and recover/separate methane, helium, carbon dioxide, oxygen and nitrogen—fully automatic, with options for unattended operation and part-load control.

Plant data:

| Feedstock: | process gases / natural gas / fuel gas |

| Capacity: | 5.000 to 60.000 Nm³/h |

| Purity: | up to 99 vol.-% |

| Pressure: | 4 – 7 bar(abs) |

| Product recovery: | up to ~98–99% (application dependent) |

Benefits

Why Process Gas Membranes?

Completely pre-manufactured skids

Unattended and automated operation

Continuous process without any moving parts

Online adjustment of recovery and product purity possible

High availability and reliability

Frequently asked questions

Questions about our process gas membranes

How are membrane systems delivered and operated?

Our membrane systems are typically delivered as modular, pre-assembled units that are ready for installation on site. Operation is straightforward: after connection to the process feed, the system is commissioned, and standardised controls allow automated, trouble-free continuous running. Maintenance is minimal thanks to robust design and reliable membrane modules, ensuring consistent performance over time.

Can membrane systems be combined with other technologies?

Mahler AGS membrane technologies are suitable for a broad spectrum of applications requiring efficient gas separation. Typical feed gas compositions include mixtures of water vapor, helium, hydrogen, carbon dioxide, oxygen, carbon monoxide, nitrogen, and methane. Depending on the specific application, process pressures of up to 160 barg can be accommodated. Given the wide variability in applications and the critical influence of operating conditions, we strongly recommend submitting an inquiry with detailed feed and product specifications. Our team of experts will then assess the feasibility and tailor a solution optimized for your specific requirements.

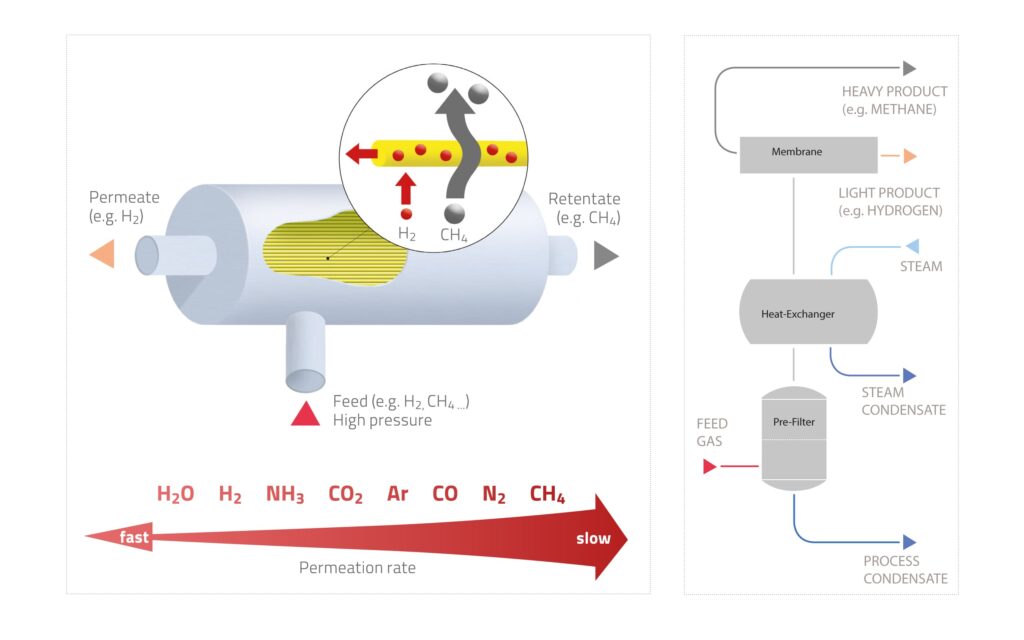

How do process membranes work?

Membrane systems for gas mixtures work by exploiting differences in the permeability of individual gas components through a selective membrane material. When a gas mixture is fed under pressure to one side of the membrane, certain gases permeate faster due to their smaller molecular size, higher diffusivity, or greater solubility within the membrane material. This creates a separation effect where the permeate side is enriched with specific gases, while others are retained on the feed side. The driving force for this separation is the pressure difference across the membrane, and the effectiveness depends on the membrane’s selectivity and permeability characteristics.

Is PSA technology or a membrane solution better for hydrogen containing gases?

Both PSA and membrane solutions have their advantages for treating hydrogen-containing gases. PSA typically achieves higher hydrogen purity (up to 99.9999 vol.%) with good recovery rates. In addition, investment costs scale significantly less as product capacity increases. Membrane systems offer simpler operation, lower capital and operating costs, and can achieve hydrogen purities up to 99% with flexible recovery rates depending on the feed gas and operating conditions. The choice between PSA and membrane technology depends on specific purity requirements, feed gas composition, pressure conditions, and economic considerations. In some cases, hybrid systems combining both technologies provide optimal performance by balancing purity and recovery.

Can membrane systems be combined with other technologies?

Yes, membrane systems can be seamlessly integrated with complementary technologies to optimize gas separation processes with regard to higher product purity and increased product yield.

Applications for our process gas membranes

Typical applications for our process gas membranes

Petrochemical and refining industry

Metallurgical and steel industry

Glass and enamel industry

Chemical and pharmaceutical industry

Food industry

Electronics industry

Technical gases

Design your Process Gas Membrane unit with MAHLER

Get expert guidance to configure membrane systems for maximum gas recovery, purity and efficiency.

Information brochure

Our Process

End-to-end expertise for your gas system

With MAHLER, you don’t just get a gas plant – you get a full-service partnership. Our end-to-end approach includes professional project management, tailored engineering, high-quality in-house manufacturing, and long-term support. Each project follows a structured process – designed to deliver maximum reliability, efficiency, and value.

01

Planning & Engineering

We analyze your requirements and design the ideal system – tailored, efficient, and ready to scale.

02

Technology & Plants

We develop and produce your plant using advanced MAHLER gas technologies and in-house manufacturing expertise.

03

Delivery & Commissioning

From procurement to on-site installation – everything is coordinated and delivered from a single source.

04

Service & Optimization

We support you with maintenance, spare parts, and continuous optimization to keep your process efficient long-term.

Contact

Start planning your process gas membrane system with our engineering experts today

Our experts are available to provide you with personalized advice. Contact us to find the best solution for your system!