Plants

High-efficient Protective Gas Systems (HN / HNX)

Mahler AGS HN/HNX protective gas generators produce a nitrogen-based protective atmosphere with defined hydrogen content. The plants use controlled combustion of hydrocarbons to meet protective-gas demands—offering high availability, long lifetime, and reliable performance.

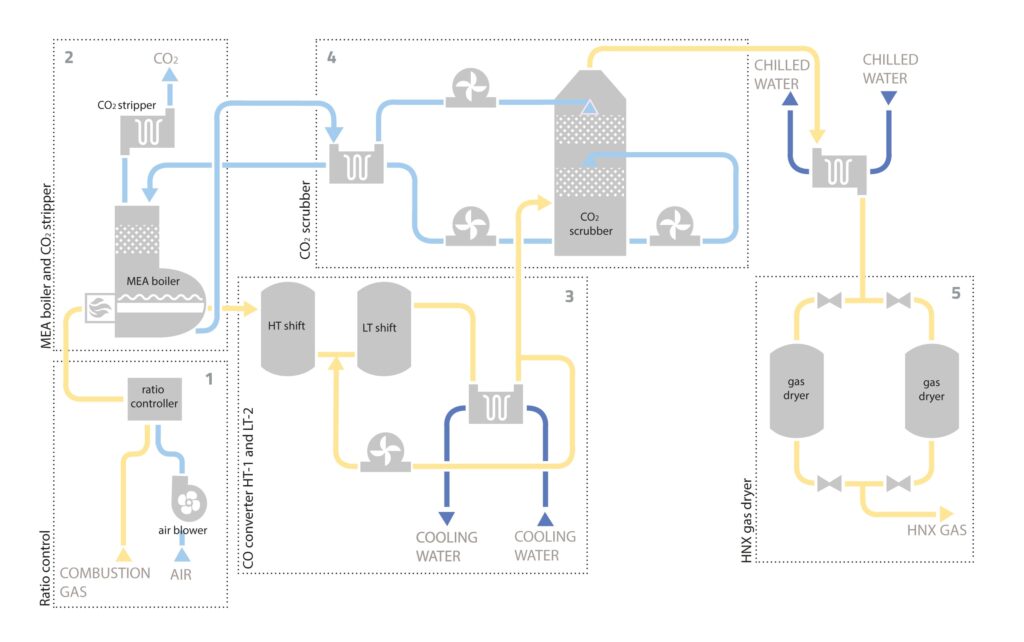

HOW MAHLER PROTECTIVE GAS PLANTS WORK

Protective Gas Generation for Heat-Treatment Atmospheres

HN/HNX plants create protective atmospheres by controlled combustion of hydrocarbons followed by cooling, drying and fine purification. The result is a nitrogen-rich gas with an adjustable hydrogen fraction—delivered fully automatically, with unattended operation and automatic load adjustment.

Plant data:

| Feedstock: | natural gas (NG), liquefied petroleum gas (LPG) |

| Product gas capacity: | 350 to 1,200 Nm³/h |

| Purity: | 1 – 12 vol.% |

| Pressure*: | about 1.1 bar(abs) |

* at exit oxygen VPSA unit; higher pressures on demand.

Benefits

Why Protective Gas Systems?

High reliability

Fully automatic and unattended operation

Independent and low-cost

on-site production

Frequently asked questions

Questions about our protective gas plants

What is protective gas and what is it used for?

Protective gas is a specially formulated mixture of gases, usually consisting of nitrogen with a specific amount of hydrogen, that is used to create an inert or reducing atmosphere. It protects sensitive materials from oxidation, contamination, and unwanted reactions during processes such as heat treatment, sintering, and metal processing.

What hydrogen content can HN/HNX protective gas plants provide?

HN/HNX plants generate protective gas on-site through sub-stoichiometric combustion of hydrocarbons (natural gas or LPG), conversion of CO to CO₂, and removal of CO₂. The hydrogen content can be customized according to customer requirements and typically ranges from 0.5 to 15 vol.%.

What capacity range do Protective Gas Generators cover?

Protective gas generators are designed for production capacities up to 1,000 Nm³/h per unit.

What are the key advantages of Mahler AGS protective gas systems?

These systems offer cost-effective, on-site production and fully automatic, unattended operation. They also provide flexibility in terms of product flow and hydrogen content. Additionally, they are skid-based and prefabricated to ensure high availability and reliability.

Applications for our protective gas plants

Typical applications for our protective gas plants

Petrochemical and refining industry

Metallurgical and steel industry

Glass and enamel industry

Chemical and pharmaceutical industry

Food industry

Electronics industry

Technical gases

Plan Your Protective Gas Plant with MAHLER

Get expert support for selecting and configuring your ideal on-site oxygen solution.

Information brochure

Our Process

End-to-end expertise for your gas system

With MAHLER, you don’t just get a gas plant – you get a full-service partnership. Our end-to-end approach includes professional project management, tailored engineering, high-quality in-house manufacturing, and long-term support. Each project follows a structured process – designed to deliver maximum reliability, efficiency, and value.

01

Planning & Engineering

We analyze your requirements and design the ideal system – tailored, efficient, and ready to scale.

02

Technology & Plants

We develop and produce your plant using advanced MAHLER gas technologies and in-house manufacturing expertise.

03

Delivery & Commissioning

From procurement to on-site installation – everything is coordinated and delivered from a single source.

04

Service & Optimization

We support you with maintenance, spare parts, and continuous optimization to keep your process efficient long-term.

Contact

Optimize your heat-treatment with reliable protective-gas generation

Our experts are available to provide you with personalized advice. Contact us to find the best solution for your system!