Plants

Hydroswing: Hydrogen Pressure

Swing Adsorption (PSA)

Mahler AGS HYDROSWING plants deliver high-purity hydrogen by separating it from synthesis gas or off-gas streams using advanced PSA technology. Reliable, efficient and tailored to your process requirements.

Advanced PSA purification for hydrogen

Advanced PSA purification for hydrogen

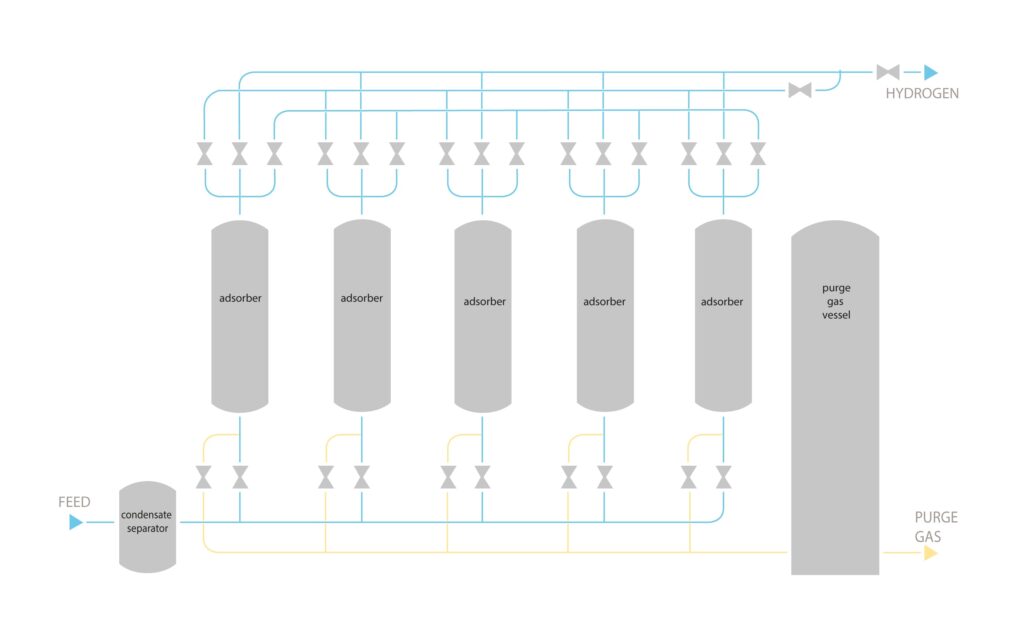

The hydroswing process is based on multibed pressure swing adsorption technology. Feed gas streams containing hydrogen are purified by selectively adsorbing impurities such as CO, CO₂, CH₄ and N₂. The result is a continuous flow of high-purity hydrogen, with recovery rates of up to 90%, produced fully automatically and without the need for operator attendance.

Plant data:

| Feedstock: | hydrogen rich gas, synthesis gas |

| Hydrogen capacity: | 100 to 20.000 Nm³/h |

| Purity: | up to 99,9999 vol.-% |

| Pressure: | 6 – 40 bar(abs) |

Benefits

Why Hydroswing?

Design for a long lifetime

High system availability and operational reliability

Fully automatic operation and remote control

Completely pre-manufactured valve-skid

Easy maintenance and accessibility

Frequently asked questions

Questions about our Hydroswing plants

What capacity range does the Hydroswing plant cover?

Hydroswing is designed for hydrogen production capacities from 100 to 20,000 Nm³/h per unit

What is the recovery/efficiency of a Hydrogen-PSA-unit?

For the purification of hydrogen in a Pressure-Swing-Adsorption (PSA) unit a recovery of approx. 78 - 86 % can be reached depending on the feed gas properties.

How does the HYDROSWING process achieve high hydrogen purity?

Hydroswing plants are fully automated pressure swing units, whose efficiency is based on the targeted selection and combination of different filling materials – the basis for high-quality product gas.

In the PSA process, impurities such as carbon monoxide, carbon dioxide and methane are selectively adsorbed at high pressure. High purity hydrogen leaves the adsorber at the top.

It is only through Mahler AGS’s decades of operating experience that the process parameters and operating conditions can be optimally adjusted to reliably produce hydrogen of the highest purity.

What is a suitable operating pressure for the hydrogen purification unit (PSA-plant)?

Typically the operating pressure of a Hydrogen-PSA-unit is between 10 and 40 bar. This range ensures compatibility with a wide range of industrial hydrogen sources as well as our Hydroform C and Hydroform M plants.

What determines the filling materials used in the adsorbers?

The type and amount of filling materials are chosen depending on the feed composition and the product requirements. Each adsorber is filled with several layers of multiple materials.

How is process control managed for consistent purity and flow?

Advanced process control combines automated valve operation, precise pressure adjustement, and continuous gas analysis. This ensures stable product quality and reliable plant operation.

How is the operation and control of Hydroswing PSA plants configured?

Hydroswing plants are fully automated and designed for remote operation. Consequently, no personnel is needed on site. They also feature automated start-up and shutdown processes, as well as the capability for load adjustment and remote monitoring.

Applications for our Hydroswing Plants

Typical applications for our Hydroswing plants

Petrochemical and refining industry

Metallurgical and steel industry

Glass and enamel industry

Chemical and pharmaceutical industry

Food industry

Electronics industry

Technical gases

Configure your Hydroswing PSA system with MAHLER

Get expert support for designing and sizing your hydrogen PSA unit – from feed gas to purity and recovery requirements.

Information brochure

Our Process

End-to-end expertise for your gas system

With MAHLER, you don’t just get a gas plant – you get a full-service partnership. Our end-to-end approach includes professional project management, tailored engineering, high-quality in-house manufacturing, and long-term support. Each project follows a structured process – designed to deliver maximum reliability, efficiency, and value.

01

Planning & Engineering

We analyze your requirements and design the ideal system – tailored, efficient, and ready to scale.

02

Technology & Plants

We develop and produce your plant using advanced MAHLER gas technologies and in-house manufacturing expertise.

03

Delivery & Commissioning

From procurement to on-site installation – everything is coordinated and delivered from a single source.

04

Service & Optimization

We support you with maintenance, spare parts, and continuous optimization to keep your process efficient long-term.

Contact

Achieve ultra-pure hydrogen with Hydroswing PSA technology

Our experts are ready to plan and configure your hydroswing plant – tailored to your hydrogen capacity, purity and recovery requirements.